Posidyne Clutch Brakes for Heavy Duty, High Cycle Applications

- Torque: 518 LB-IN to 79,000 LB-IN

- HP: 1 HP to 1500 HP.

- Pneumatic or Hydraulic Actuation

- Cooling: Basic, Fan, Water and Forced Lube

- Optional C-Face or Piggyback Available

- Washdown, Marine Duty or Hazardous Duty

High Cycle—Up to 300 CPM

Long Life—5 to 10 Times Longer

Heavy Duty Totally Enclosed Housing

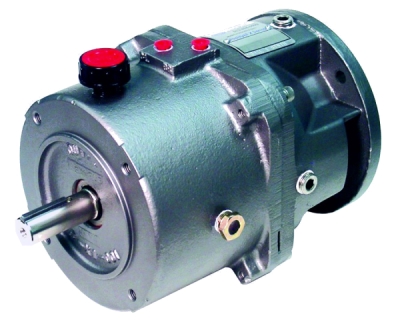

Posidyne Size 1.5 Clutch Brake with Lightweight Housing

- Torque: 518 LB-IN to 79,000 LB-IN

- HP: 1 HP to 1500 HP.

- Pneumatic or Hydraulic Actuation

- Cooling: Basic, Fan, Water and Forced Lube

- Optional C-Face or Piggyback Available

- Washdown, Marine Duty or Hazardous Duty

High Cycle—Up to 300 CPM

Long Life—5 to 10 Times Longer

Heavy Duty Totally Enclosed Housing

Posidyne X-Class C-Face Clutch Brakes Value Engineered for OEM Applications

- Torque: 90 LB-IN to 1,000 LB-IN

- HP: 1 HP to 25 HP

- Pneumatic or Hydraulic Actuation.

- Fits NEMA 56C to 215T Frames Motors

- Optional Input Shaft and Foot Mounting Available

- Washdown, Marine Duty or Hazardous Duty

High Cycle—Up to 300 CPM

Long Life—5 to 10 Times Longer

Heavy Duty Totally Enclosed Housing

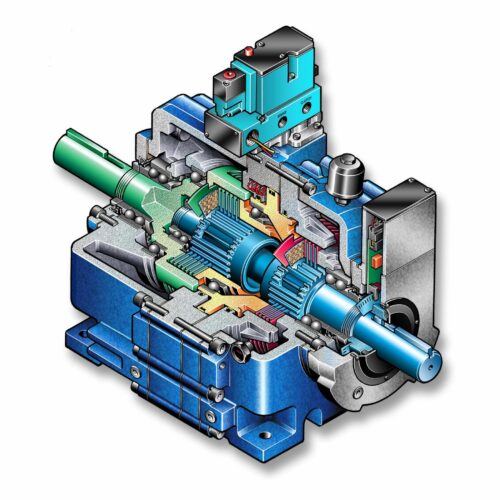

Posidyne clutch brakes consist of a clutch stack and brake stack made up of alternating friction discs and drive plates connected to a splined output shaft. The drive plates are connected to the input shaft or housing.

A centrally located air (or hydraulic) actuated piston exerts pressure on either the clutch stack or brake stack – never both.

Adjustable actuation pressure on the friction stack establishes the torque transmitted by that stack, and is independently adjustable.

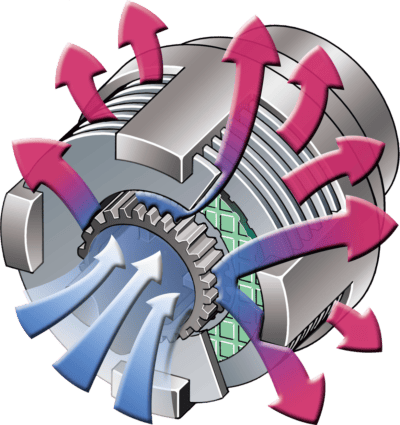

Oil Shear Technology

Transmission fluid circulating through the unit flows through an open center hub, through the friction stack, and out to the housing.

Cooling occurs as the fluid runs back to the bottom of the unit to be recirculated.

This system, called Oil Shear Technology, prevents wear on the friction surfaces, removes heat from the engagement area, and lubricates all internal parts.