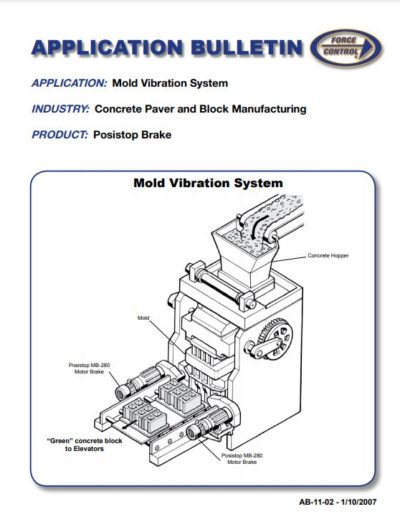

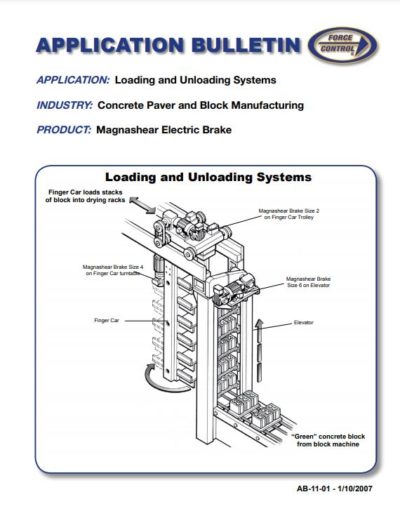

Concrete Block plants typically rely on one or two highly sophisticated block making machines for their production. If one part of the machine fails, it results in extremely high downtime cost. Consequently, block plants require reliable parts and components in order to stay competitive in the industry. In the 1970’s, Force Control originally designed and manufactured the Posidyne oil shear clutch brakes for the largest block machine OEMs. These units have been running successfully on many machines for 50 years worldwide and Force Control will continue to service the industry with a full line of clutch brakes and motor brakes. You can rely on Force Control products to provide years of trouble free operation with no maintenance and reduced downtime.

Application Solutions

| Model | Clutch (PSI) | Brake (PSI) |

|---|---|---|

| 05-434 | 30 | 30 |

| 10-410 | 30 | 30 |

| 11-010 | 70 | 50 |

| 11-206 | 70 | 50 |

| 14-201 | 50 | 32 |

| 20-207 | 70 | 50 |

Air Supply

Dry and clean air supply and properly set air pressures are the most critical factors for your Posidyne’s lifespan. We recommend using high quality regulators and gauges to extend the life of your Posidyne.

Posidyne models have top and bottom ports. We recommend using the bottom ports which adds an extra layer of defense against debris that could contaminate the unit.

Installation Tips

Proper installation requires the feet to be shimmed so that the housings are not twisted when the unit is bolted down.

Belt drives need to be properly aligned and tensioned. Routinely inspect sheaves and belts for wear as low or high belt tension could damage the Posiydne.

Lubrication

Force Control’s Posidynes use Mobil ATF Type F transmission fluid. We strongly recommend using this lubricant as it results in the longest service life compared to other fluids. If you cannot find Mobil ATF Type F, use one of the following approved fluids:

- Havoline ATF Type F

- Chevron ATF Type F

- Kendall ATF Type F