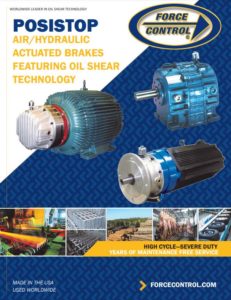

Force Control provides a rugged line of brakes for the harsh environment of today’s Material Handling operations. The key drivers of the industry are safety and reliability and Force Control products are designed to exceed these expectations. Oil Shear Technology, at the heart of every Force Control product, offers a longer service life with no down time or maintenance. Our electrically, pneumatically and hydraulically released brakes can be ordered with a hazardous duty certification in order to comply with the industry’s safety standards.

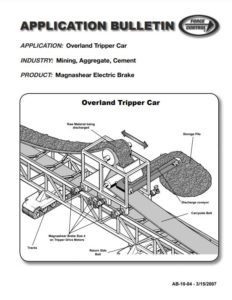

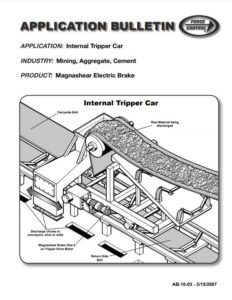

Force Control provides a rugged line of brakes for the harsh environment of today’s Material Handling. Whether electric, pneumatic or hydraulic actuation, Force Control has the brake with the torque, features and reliability you need to keep your facility running. You can find our brakes running around the clock on Rail Car Positioners, Dumpers, Positioner Arms and Tripper Cars. Our Oil Shear Technology means more accurate positioning, longer life and no down time or maintenance.

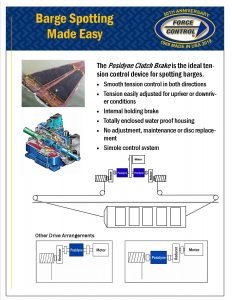

Terminals need more than standard equipment when operating in high-stress, heavy-duty scenarios. Downtime can be costly, often incurring demurrage fees when cargo loading or unloading exceeds the set timeframe. These charges add up quickly, especially with high cargo volumes and tight schedules.

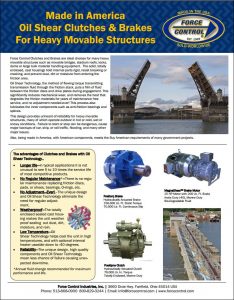

At Force Control Industries, we design specialized braking systems that address the exact needs of your terminal. Our products offer robust performance, optimizing both safety and efficiency in industries managing railcars, barges, containers and more. Built tough for the long run, our solutions are crafted for the demanding nature of terminal environments.

Enhancing Terminal Operations with Precision

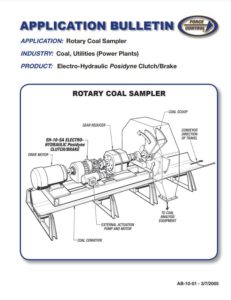

In terminal environments, precision and safety are paramount. To meet these needs, our heavy-duty brakes offer the durability required for intense, repetitive tasks. Terminals managing rail car positioners with our brake motors can accurately align and move railcars for efficient loading and unloading, reducing the potential for operational delays. Our brakes used on rail car dumper systems, paired with high-torque, hazardous duty brakes, handle materials safely in industries where dust and hazardous materials pose risks.

In high-risk environments, especially those involving combustible materials, safety measures must be top-tier. Our hazardous duty brakes are designed to prevent accidents in terminals where safety is a priority. For chemical processing and petroleum distribution sectors, these brakes offer a crucial layer of protection, ensuring your operations are secure while reducing the risk of incidents.

Solutions for Hazardous Environments

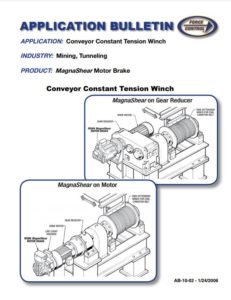

Terminals operating in volatile environments demand a higher level of protection. Our explosion-proof brakes are meticulously designed to eliminate any chance of ignition, providing reliable protection even in environments containing flammable gasses, liquids, or dust. These brakes are rigorously tested to meet the highest safety standards, offering peace of mind in high-risk applications. Pair these with our winch brakes to ensure controlled material handling during lifting operations, reducing the risk of equipment failure and ensuring the safe transfer of goods.

These brakes undergo rigorous testing, including validation through failure mode and effects analysis (FMEA) and compliance with ISO and ATEX standards, guaranteeing durability and performance under extreme conditions. Leveraging innovative oil shear technology, our brakes reduce friction and eliminate “spark points,” further minimizing the risk of ignition while extending service life.

Versatile Solutions for Diverse Terminal Needs

We understand that terminals are diverse and require equipment tailored to specific operational demands. From moving massive loads to navigating confined spaces, our brakes deliver the precision and control necessary to maintain smooth operations, ensuring minimal downtime and maximum efficiency.

Technical Specifications That Matter

Our products are designed with industry-specific requirements in mind:

- Heavy duty brakes: Engineered for extreme conditions, offering extended service life with minimal maintenance.

- Rail car positioners: Provide precise control using our brakes on positioners, reducing misalignments during critical loading/unloading processes.

- Hazardous duty brakes: Explosion-proof and built for high-risk environments where safety cannot be compromised.

- Severe Duty Brakes: Designed for harsh environments with materials to combat corrosion issues which ultimately lead to failure.

- Washdown Duty Options: Protect against moisture, caustic spray, and chemicals with features like nickel-plated or stainless steel shafts, non-metallic breathers, and Steel-It epoxy coating.

Drive Your Terminal Operations Forward with Us

Here at Force Control Industries, we focus on providing top-tier material handling solutions that keep your terminal operations running smoothly, safely, and productively. Our advanced braking systems and positioners are designed to endure even the harshest environments, ensuring long-term efficiency and reliability for your facility. Partner with us to elevate your terminal performance today.

Reach out to our team to find the right braking systems and positioners for your terminal. Together, we’ll ensure your facility stays ahead in safety and efficiency.