Dynamic Stopping Brakes – Not Just Holding Brakes

High Reliability – Low Maintenance Braking

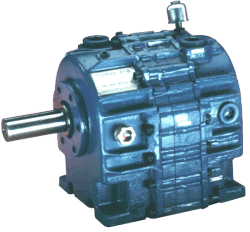

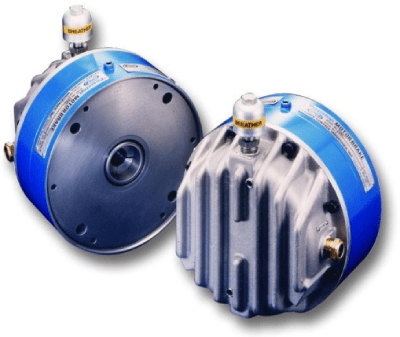

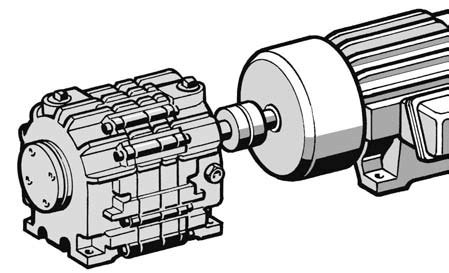

Designed with Oil Shear Technology the Posistop and MagnaShear Motor Brakes are dynamic stopping brakes designed to mount on the back of a brake motor. They can survive the harsh environments of mining, manufacturing, material handling as well as packaging and food processing with minimal maintenance and no adjustment-ever. The totally enclosed rugged housings keep dirt and moisture out while reducing noise and extracting heat.

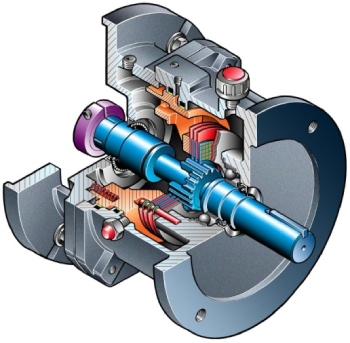

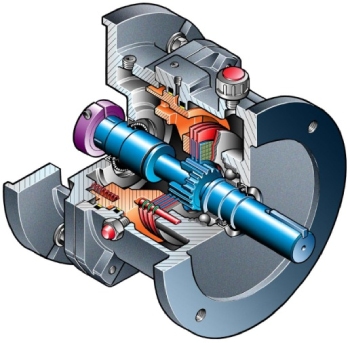

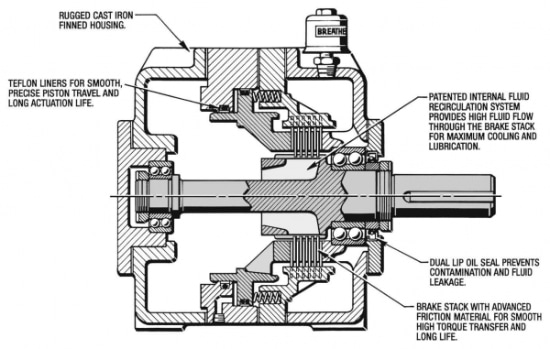

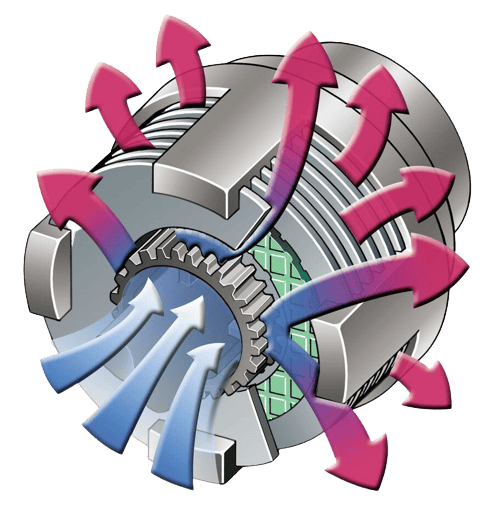

Oil Shear Technology reduces the contact between friction disc and drive plates by providing a film of transmission fluid between the parts. This delivers a smooth quiet torque for precise stopping while greatly reducing wear and eliminating adjustment requirements for the life of the brake. Designed based on 40 million cycles service life has proven to be 5 – 10 times that of ordinary dry friction brakes.

These brakes come in many styles such as motor brakes, coupler brakes, assembled brake motors, and foot or flanged mounted and air, hydraulic, or electric actuation.

Low Maintenance – No Adjustment Over the Life of the Brake

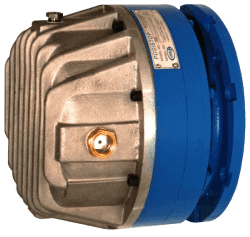

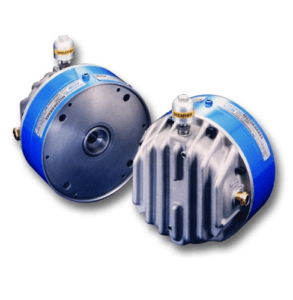

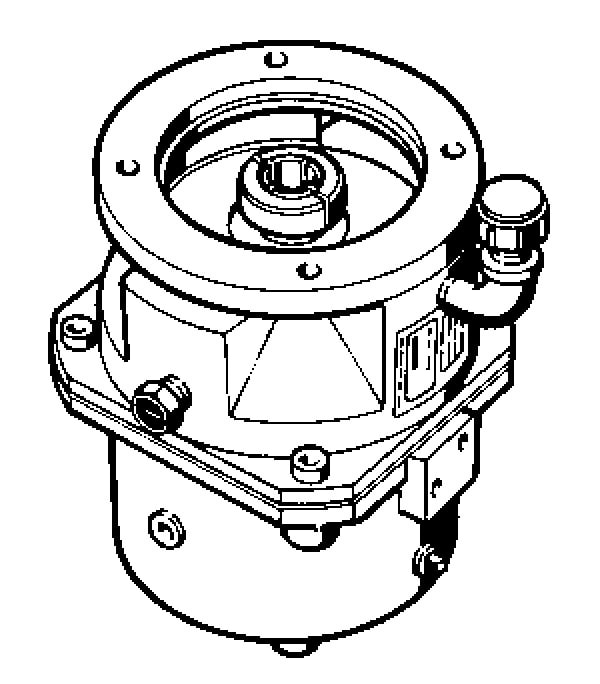

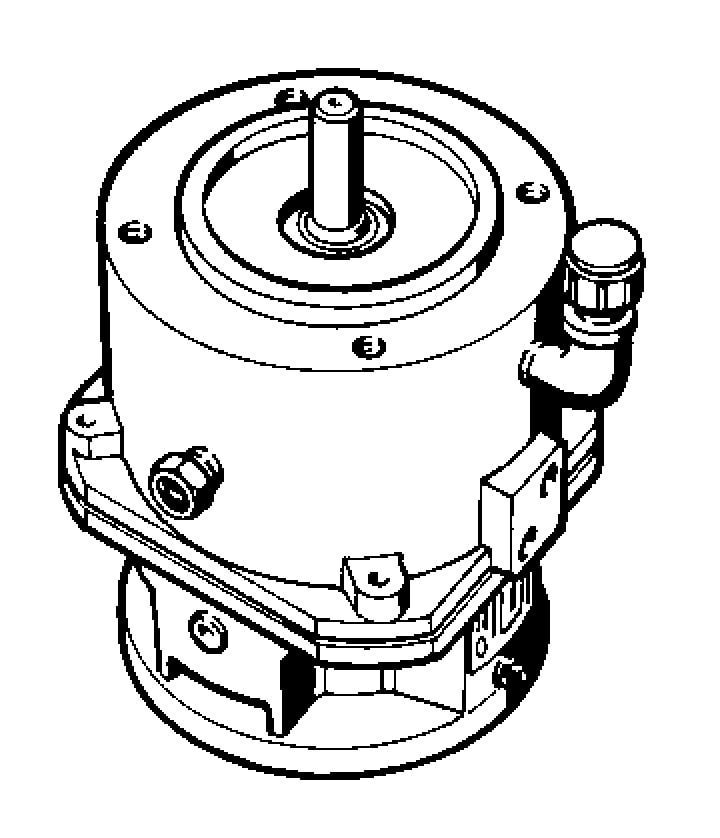

Posistop Pneumatic Motor Brakes

- Torque: 6 LB-FT to 2,030 LB-FT

- Fit NEMA 56C to 449T Motor Frames

- Pneumatic or Hydraulic Actuation

- IEC and Custom Mounting Available

- Washdown, Marine Duty and Hazardous Duty

- Can be furnished as an Assembled Brake Motor

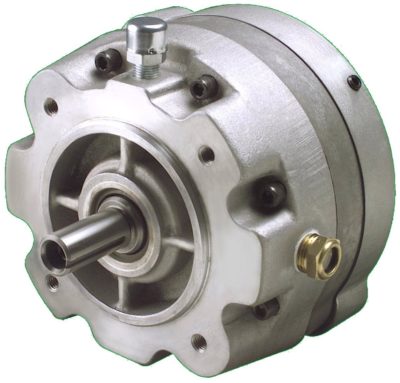

The Posistop Motor and Coupler Brakes are designed for long life with minimal maintenance in severe and critical applications. They are typically furnished as spring set, pressure release brakes however pressure set spring release is available in some models. The multiple disc design reduces inertia of the brake putting less load on the motor and improves efficiency each cycle.

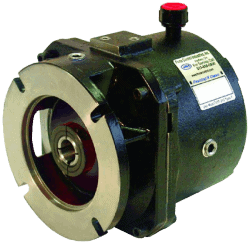

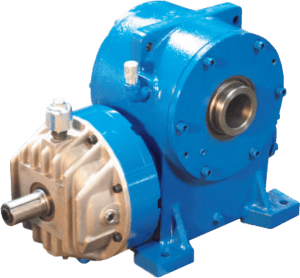

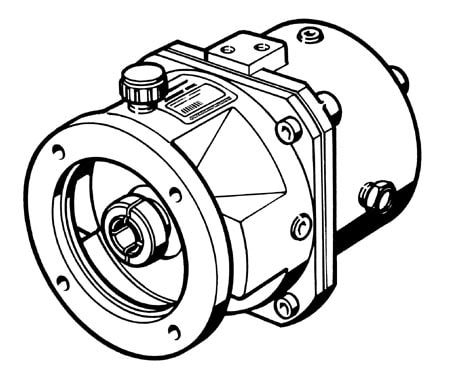

Posistop motor brakes are designed to mount to the back of brake motors, and the coupler brakes are designed to mount to the drive end of the motor, often between the motor and reducer. Coupler brakes can also be used on servo motors.

- Up to 10 times longer life

- Minimal Maintenance

- No Adjustment – Ever!

- Air or Hydraulic Actuation

- Horizontal or Vertical Mounting

- Dust, Dirt, and Moisture Proof

Five model sizes offer torque from 6 Lb. Ft. to 2,030 Lb. Ft. and fit 56 frame up to 440 frame motors. Special flanges mountings can be furnished such as IEC, servo, or other flange sizes.

The standard shaft connection is a quill using a tapered collet providing a 360º clamped connection. Other quills are available including splined and bore and keyway.

The totally enclosed sealed housing eliminates dust, dirt, moisture, and fumes from causing internal damage. Also using an hazardous duty valve the Posistop brakes can be used in hazardous environments.

Posistop brakes are designed as dynamic brakes, in other words they can dynamically stop a load as well as hold it. The high thermal capacity allows higher cycle rates, and heavier loads.

The secret to the long life and minimal maintenance is Oil Shear Technology. Utilizing transmission fluid circulating through the disc stack the friction surfaces are protected from mechanical contact during dynamic engagement and the heat is removed via the fluid to the housing to be cooled. This nearly eliminates friction disc wear. The friction stack is typically not replaced as a regular wear item but only during rebuild. Because there is virtually no wear there is no need to adjust the brake for wear as is necessary with dry friction competitors. By reducing friction disc wear, removing heat, and lubricating the internal components, up to 10 times longer life can be expected without constant adjustment and repair.

POSISTOP BRAKE OPTIONS

HAZARDOUS DUTY

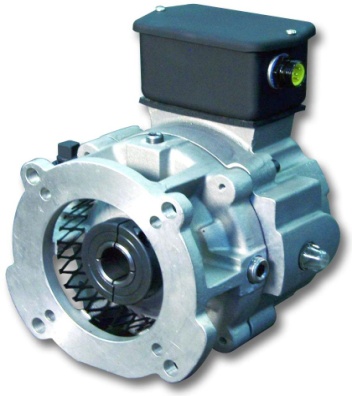

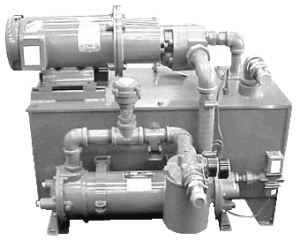

OIL-TO-AIR EXTERNAL COOLING

Transmission fluid is circulated through an external oil-to-air heat exchanger (oil-to-water is available), through a filter and back into the unit. This system provides the ultimate life for the brake in addition to handling extremely high thermal loads.

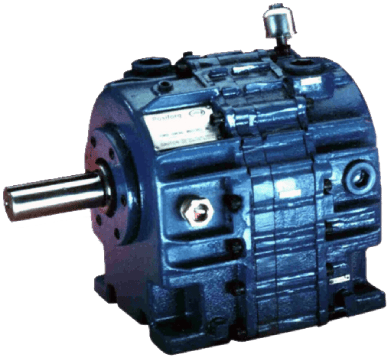

GEARBOX MOUNTING

FORCED LUBE COOLING

WASHDOWN & MARINE DUTY

SERVO MOTOR BRAKE

ASSEMBLED BRAKE MOTOR

The manifold mounted valve improves response time, positioning accuracy and reduces installation time. Particularly useful for high precision applications.