The Positorq braking system is designed as totally enclosed system with air or hydraulic actuation for hazardous environments, and fresh or salt water applications. Some examples of ideal applications include anchor winches, mooring winches used in Offshore Oil and Gas well applications. Another application is the drilling rig drawworks. Replacing the Baylor eddy current brake on older system is a great upgrade as now you have a smooth brake for drilling, high capacity dynamic brake for tripping, and a static holding brake.

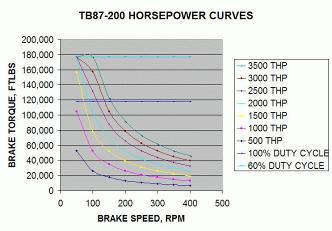

These Positorq brakes are rated up to 180,000 Lb. Ft. continuous slip torque, and 300,000 Lb. Ft. static holding torque and can dissipate up to 3000 thermal horsepower.

A major advantage for Positorq brakes is Oil Shear Technology. Oil Shear Technology provides smooth engagement, higher heat dissipation, negligible wear on friction discs, bearings, and splines, and quiet operation. This all contributes to higher productivity, lower maintenance cost, and better return on investment.

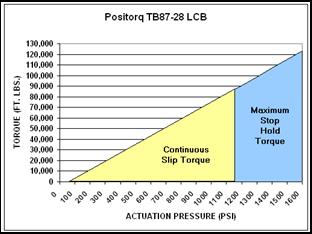

The Positorq Brakes operate by applying pressure on a piston or pistons clamping the friction stack. The tighter the clamping force the higher the torque, and it is not affected by speed. The actuation medium can be pneumatic or hydraulic. The hydraulic actuation is more controllable.

Transmission fluid in the brake transmits torque between the friction disc and drive plates providing the torque. As this fluid is heated it is pumped back through a Forced Lube Cooling Unit that has oil-to-water or oil-to-air cooling, filters, pumps and reservoir. The FLCU allows the brake to be very compact, with low inertia.

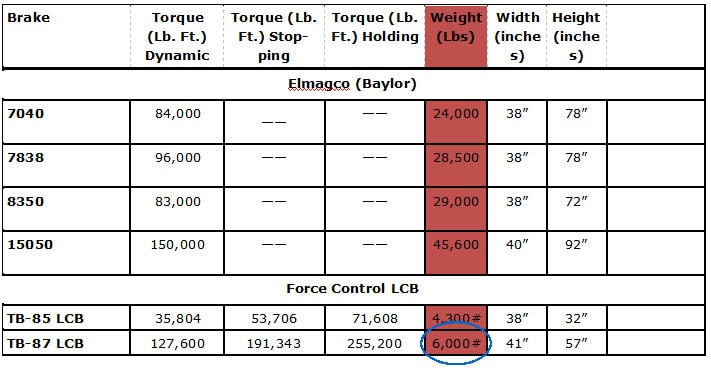

Replace your Elmagco 7838 Brake with the Force Control TB-87 LCB Positorq Oil Shear Load Control Brake and trip faster, drill smoother, and make your operators happy. The TB-87 Positorq brake will operate consistently from 0 RPM to full speed. Torque is linear to actuation pressure (not speed sensitive) making the operation simple, and consistent. Oil shear technology means no adjustment – ever, and wear is minimal meaning years of service between rebuilds.