Dynamic Stopping Brakes – Not Just Holding Brakes

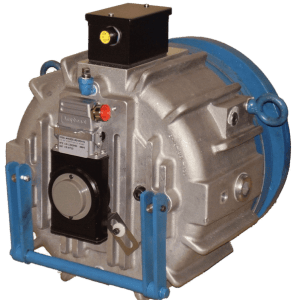

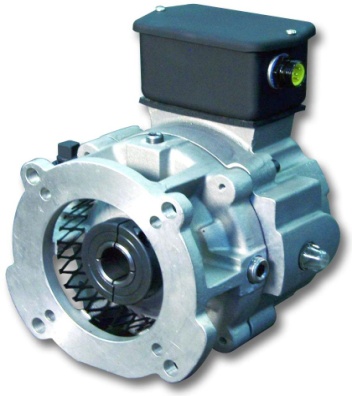

Magnashear Electric Motor Brake

- Torque 6 Lb. Ft. to 1250 Lb. Ft.

- Fits NEMA Frame 56 to 440 motor frames.

- Spring Set – Electric Release

- IEC and Custom available

- Clamped-Split-Quill saves motor shaft and keyway

- Washdown, Marine and Hazardous Duty Options

- Manual Release, lock out, and released indicator available

- Can also be furnished as an assembled brake motor

High Reliability – Low Maintenance Braking

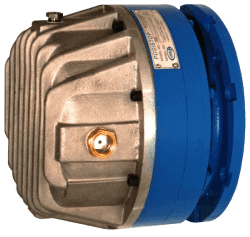

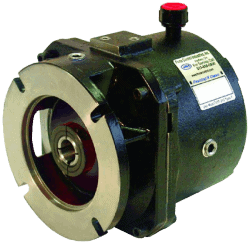

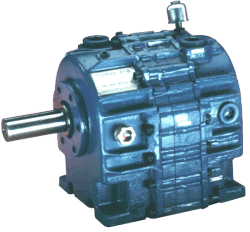

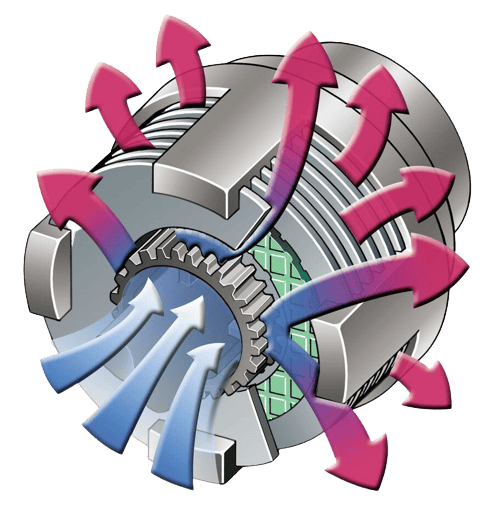

Designed with Oil Shear Technology the Posistop and MagnaShear Motor Brakes are dynamic stopping brakes designed to mount on the back of a brake motor. They can survive the harsh environments of mining, manufacturing, material handling as well as packaging and food processing with minimal maintenance and no adjustment-ever. The totally enclosed rugged housings keep dirt and moisture out while reducing noise and extracting heat.

Oil Shear Technology reduces the contact between friction disc and drive plates by providing a film of transmission fluid between the parts. This delivers a smooth quiet torque for precise stopping while greatly reducing wear and eliminating adjustment requirements for the life of the brake. Designed based on 40 million cycles service life has proven to be 5 – 10 times that of ordinary dry friction brakes.

These brakes come in many styles such as motor brakes, coupler brakes, assembled brake motors, and foot or flanged mounted and air, hydraulic, or electric actuation.